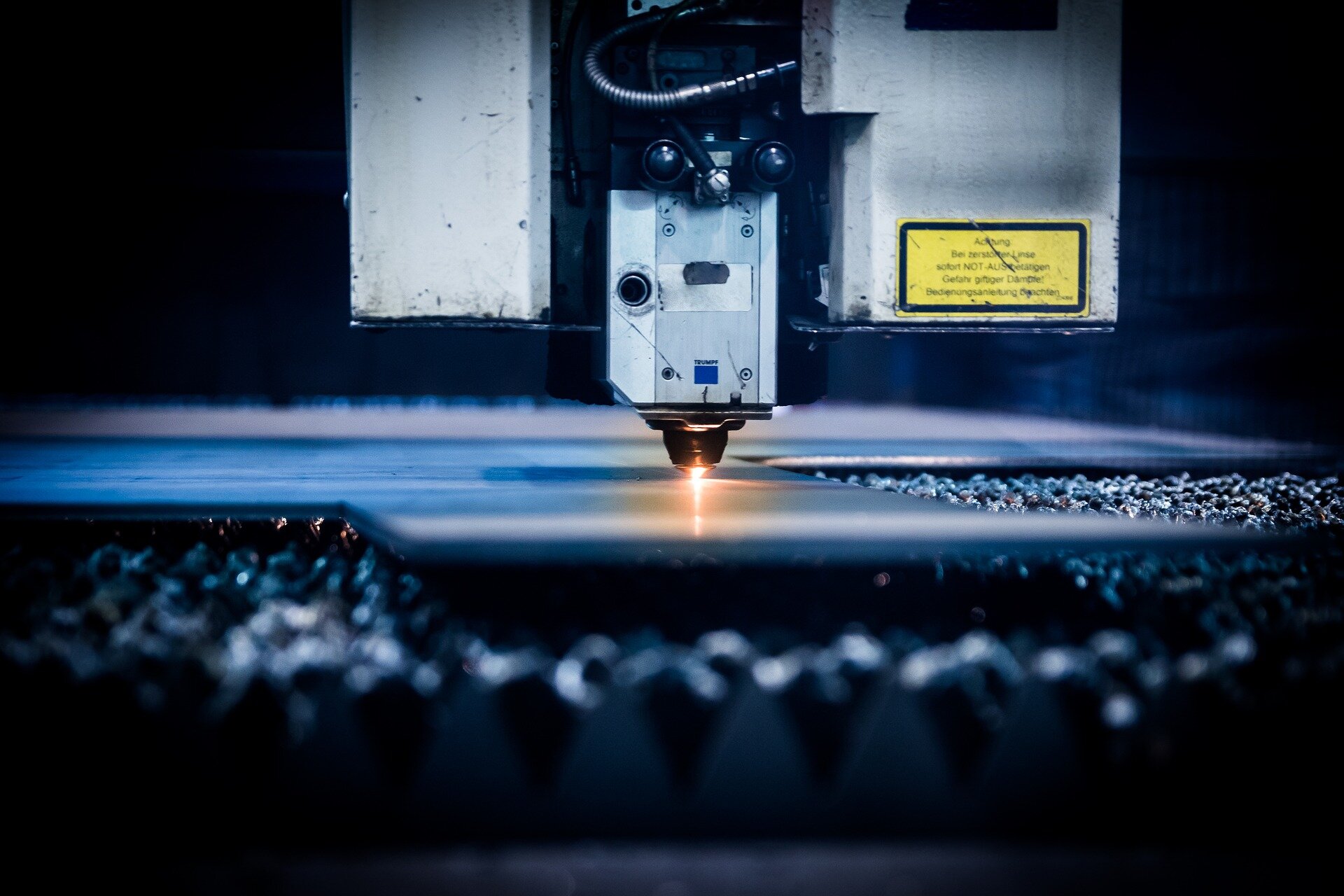

If fiber lasers seem like they’re from the future, it’s because they are. They are the latest in metal cutting machinery, and are some of the most efficient of their kind. This game-changing technology has ushered in a whole new era of metal cutting, and the science behind it is fascinating.

Have you ever wondered how fiber lasers work? Not only do they cut metal at hyper fast rates, but they may increase operational efficiency more than you may think.

Similar to how fiber optic cables work for data, fiber lasers trap light along banks of diodes that are amplified through cables. The light along the cables are straightened and then focused by a series of lens onto the material being cut.

Fiber lasers have an active medium of an optical fiber that has been doped in rare elements; typically, erbium, ytterbium, neodymium, thulium, praseodymium, holmium or dysprosium. The fiber that is being used is placed at the center of the laser. While both CO2 and crystal lasers exist, fiber lasers are known to be the newest and most efficient laser type. According to one source, fiber lasers are supposedly 200% more efficient than traditional CO2 lasers. Depending on the doped fiber, the material may play a big difference in the laser’s efficiency. Photons that come from the laser’s core are refracted many times in a series of mirrors, called the Bragg Grating.

As the laser passes through the fiber, the doped inner core refracts light in the undoped outer core. The result is an amplified beam that passes through the fiber and onto the cutting material.

Fiber lasers have some of the fastest speeds on the market. Depending on the thickness of the material, fiber lasers can decrease production times, throughputs, and even servicing costs, when compared with other cutting styles.

How do Mitsubishi Fiber Lasers Work?

Different focal diameters correspond with different material thicknesses.

The fiber of a Mitsubishi fiber laser is doped in Yitterbium, a silvery-white metal that allows for superior amplification of the lasers. The fiber lasers can go up to 8kW, with a beam outer diameter of 140-400 microns. The difference between a regular fiber laser and a Mitsubishi Fiber Laser is that, unlike traditional fiber lasers, the Mitsubishi Fiber Laser contains a zoom head that can shift its diameter. This is useful for different types of thicknesses, to adjust how effectively the material will be cut.

Lasers can be a big capital expenditure for a company. When it comes to selecting what will help your operations, Mitsubishi can be a game changer. Not only are they efficient and fast, but they are built in the highest of quality. When it comes to machines that are built to last, MC Machinery’s Mitsubishi lasers are some of the best. These industrial metal cutting machines are built with options to automate every single part of the process. Mitsubishi provides installation, service and warranties on all of their machines.

How to Learn More

Have any questions? Call us at Carlson Fabrication Solutions at (781) 937-9599 or at reach out to us via email at info@carlsonfab.com.

![The Science Behind How Fiber Lasers Work [With Mitsubishi]](https://images.squarespace-cdn.com/content/v1/5653419fe4b0280166a0f5ee/1610034462913-HC9N0DMUTB9Z3U0SD25G/ADVANCED+eX-F+Series+Layout.jpg)