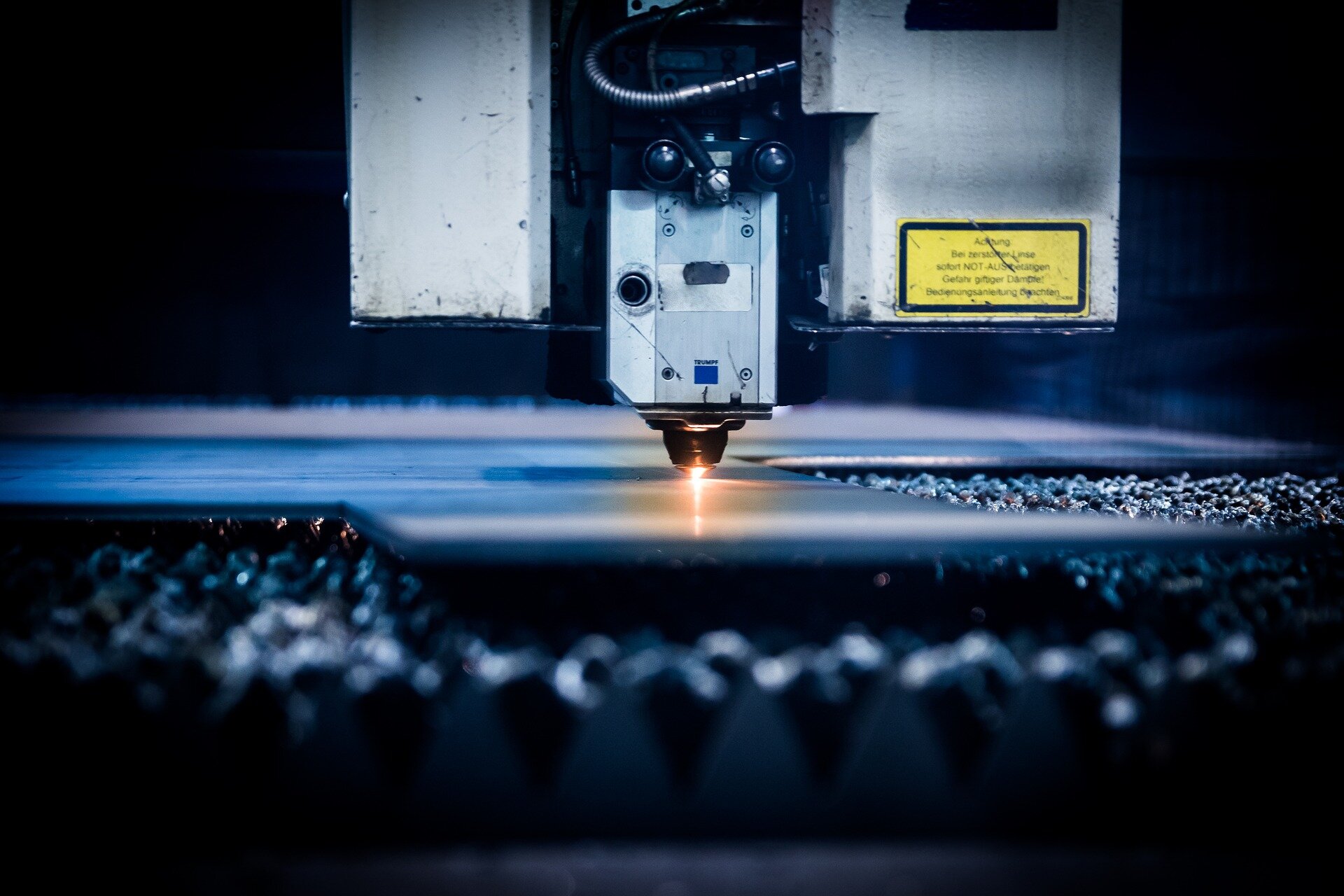

The manufacturing industry is being hit with a massive labor shortage. As new demand surges for skilled labor, the technology of manufacturing in most areas have been lacking. For this reason, Mitsubishi released their all-new GX-F Advanced fiber laser, with AI capabilities to allow for non-stop processing.

Artificial Intelligence is the future of manufacturing.

How does AI work in manufacturing?

Depending on the tasks desired to complete using the technology, AI is used to teach and then test the machines to learn optimization patterns. In the case of Mitsubishi’s GX-F Advanced fiber laser system, artificial intelligence is used to optimize gas usage. As AI implies, the program is intelligently programmed to teach and deploy the best strategy to cutting metal. The result – a machine that constantly cuts better and better. It is as if a production operator never stopped learning while on the job – and how often does this happen?

Your company’s next best employee will be automated. AI is used to optimize machines on its cutting accuracy and effectiveness while minimizing the resources used and problems that may occur. In other words, it is everything that a typical operator may continue to do while on the job – but without the operator. This saves costs and the risks associated with traditional low-skilled production operators in a manufacturing facility.

AI can be used in a variety of ways for cost savings. Anywhere there is a metric to optimize for, AI can be put to use. For example, if you need to maximize power consumption, machines can take consistent readings and figure out what processes drain the most amount of energy, and then shift processes to minimize its usage. Similarly, when the machine knows what the costs are associated with using certain resources and the like, then AI can figure out the best ways to save costs and alter how much time is spent on certain processes to produce better results.

How does the GX-F Advanced fiber laser work with AI?

We won’t spend time talking about this machine’s specifics, but you can find them here. To use artificial intelligence, the general conditions in the machine are adjusted and corrected in real-time. What this means is that while the fiber laser machine runs and learns more, it will begin to optimize itself. Its cutting system is intelligent, meaning that it constantly adjusts to what is required for it. The GX-F advanced also provides online job scheduling and runtime estimates. With the operations being accessible remotely, the machine operators can set up jobs even when they’re not on the production floor.

The best part of these machines is the package that these lasers include. Not only do these machines produce high-quality results, but all service and support are done through Mitsubishi themselves. In other words: Everything is done through the manufacturer. That is, everything aside from the sale itself – which is why Carlson Fabrication Solutions can help you find and select the best fiber laser for your manufacturing business. We act as your consultants, and only want our customers to purchase what is truly best for their metal manufacturing business.

Do you have any questions about Mitsubishi lasers?

Contact us at info@carlsonfab.com or at (781) 937-9599

![The Science Behind How Fiber Lasers Work [With Mitsubishi]](https://images.squarespace-cdn.com/content/v1/5653419fe4b0280166a0f5ee/1610034462913-HC9N0DMUTB9Z3U0SD25G/ADVANCED+eX-F+Series+Layout.jpg)